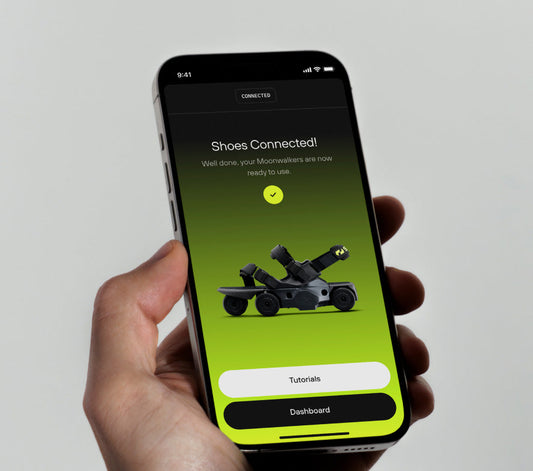

Welcome, proud owners of the cutting-edge Moonwalkers from Shift Robotics! As you revel in the excitement of your purchase, it would be insightful to take you behind the scenes. This short read will walk you through your Moonwalker's meticulous inspection process before it arrives at your doorstep. We believe transparency fosters trust, so let's delve right in!

Step 1: Mechanical Part Inspection

The first technical step involves a basic mechanical part inspection. We conduct a full dimensional review, checking the manufacturing sizing and specs where some need to be controlled within half the size of a human hair. This ensures every part fits together with utmost precision, which is crucial for the flawless functioning of your Moonwalkers.

Step 2: Material Inspection

Next, we perform a rigorous material inspection to ensure strength and durability. Through various material tests performed on a batch samples basis, such as tensile elongation and hardness testing, we confirm the material is sound, uniform, and up to the demanding standards of lunar conditions.

Step 3: Gearbox Subassembly Inspection

With the motor mounted to the fully assembled gearbox, we drive the motor to break in the gearbox for a set period of time prior to any electronics integration. This process guarantees that the gearbox and motor assembly operate with minimal friction, vital for the Moonwalker's movement and acoustic performance.

Step 4: Electronics Fabrication and Inspection

Electrical components form the heart of your Moonwalker's smart functionality. We fabricate and assemble the various PCB boards within your Moonwalkers and put them through rigorous unit testing to ensure that every functionality of our electrical systems is up to spec, from the safety features of the battery management system to the power output of the motor driving circuitry.

Step 5: System-Level Tests

After the electronics are sealed into the gearbox, we conduct system-level tests and calibrate the motor. There are minute differences between every engine, and since our tolerances are so precise, we calibrate each Moonwalker individually to ensure they respond optimally to your commands.

Step 6: Wheel Mounting

The wheels are pressed on with our automated pneumatic jig and then fastened to exacting torque specifications to guarantee that they are securely attached and ready for action.

Step 7: Adding the Foot Plate and Walking Test

Next, we secure the footplate and conduct a walking test with emergency stops to assess overall functionality and braking. This is the final quality assurance check to verify that your Moonwalker can move effortlessly with the agility and precision you'd expect.

Step 8: Battery and Charging Port Tests

Finally, we drain the battery levels to 30% due to safety for shipping. We also test the charging ports to confirm they function correctly and meet the necessary standards.

This thorough, end-to-end inspection process allows us to ensure that your Moonwalker is not just a marvel of engineering but a reliable, durable, and high-performing transportation utility. Rest assured; your Moonwalkers have been designed and validated to meet any condition of lunar exploration while providing an unmatched user experience. We hope this peek behind the scenes helps you appreciate the meticulous attention to detail that goes into every Moonwalker from Shift Robotics. Happy Walking!