Our Vision

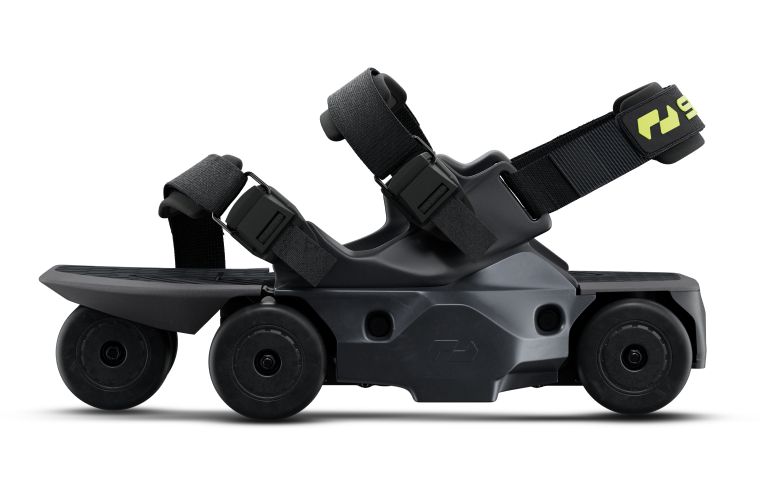

We are dedicated to advancing and empowering human movement by developing the world’s first

wheeled exoskeleton, enabling people to move further, faster, and with greater ease than ever before.

How it started

Xunjie Zhang

Founder of Shift Robotics

“Walking on Moonwalkers feels like your favorite walk has been given wings. You catch fragments of lives happening around you – laughter from a balcony, coffee brewing through an open shop door, the metallic tang before rain. The sun warms your face or wind pushes against you, making you present in ways screens and walls never do. Now you're gliding past at the perfect speed, fast enough to be practical, slow enough to still be here. You still change direction on whims, still pet that dog, still feel the city's texture beneath you – but with a subtle superpower, as if you've unlocked a secret mod for urban life.”

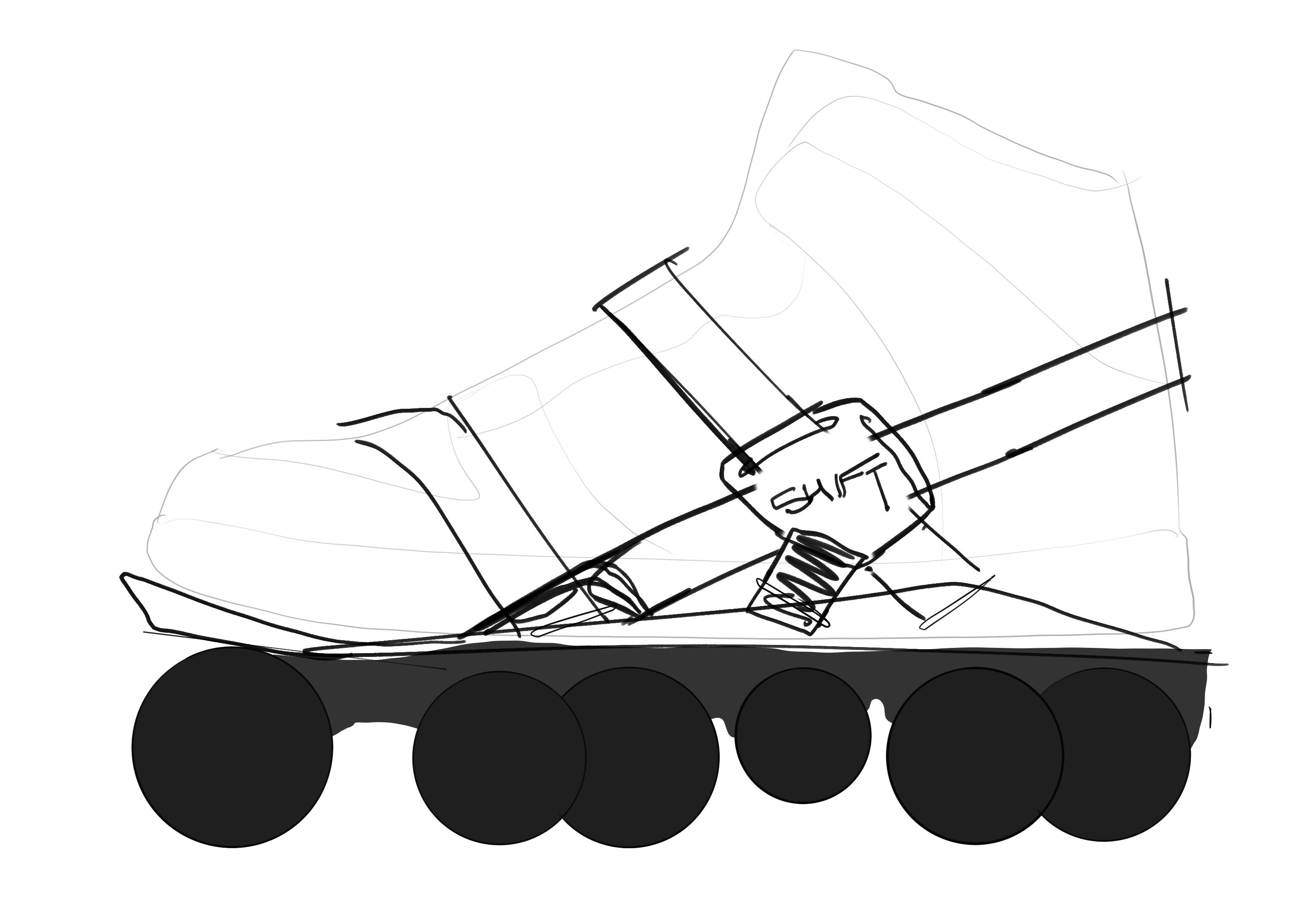

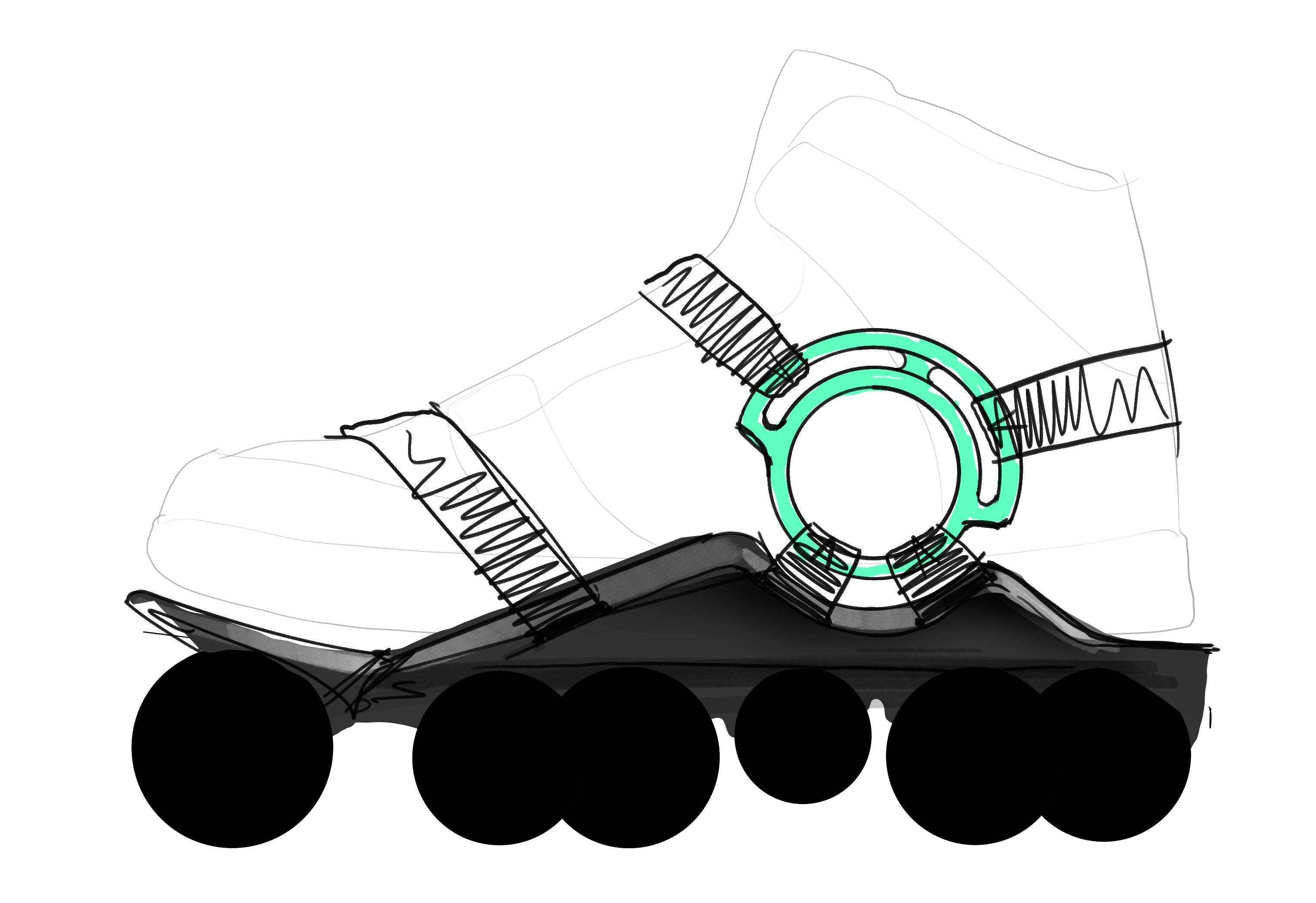

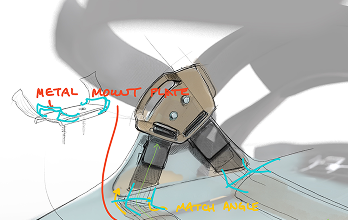

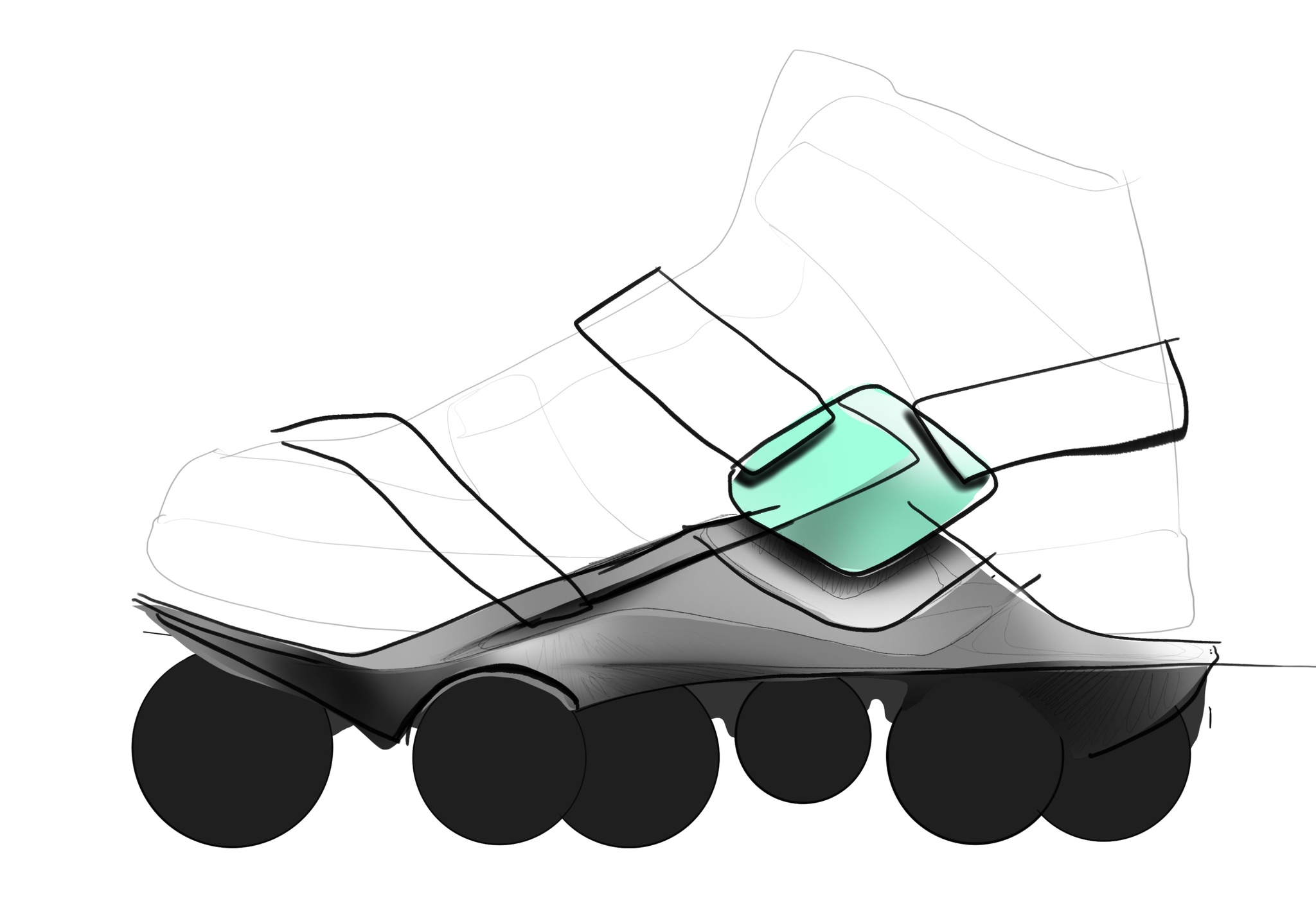

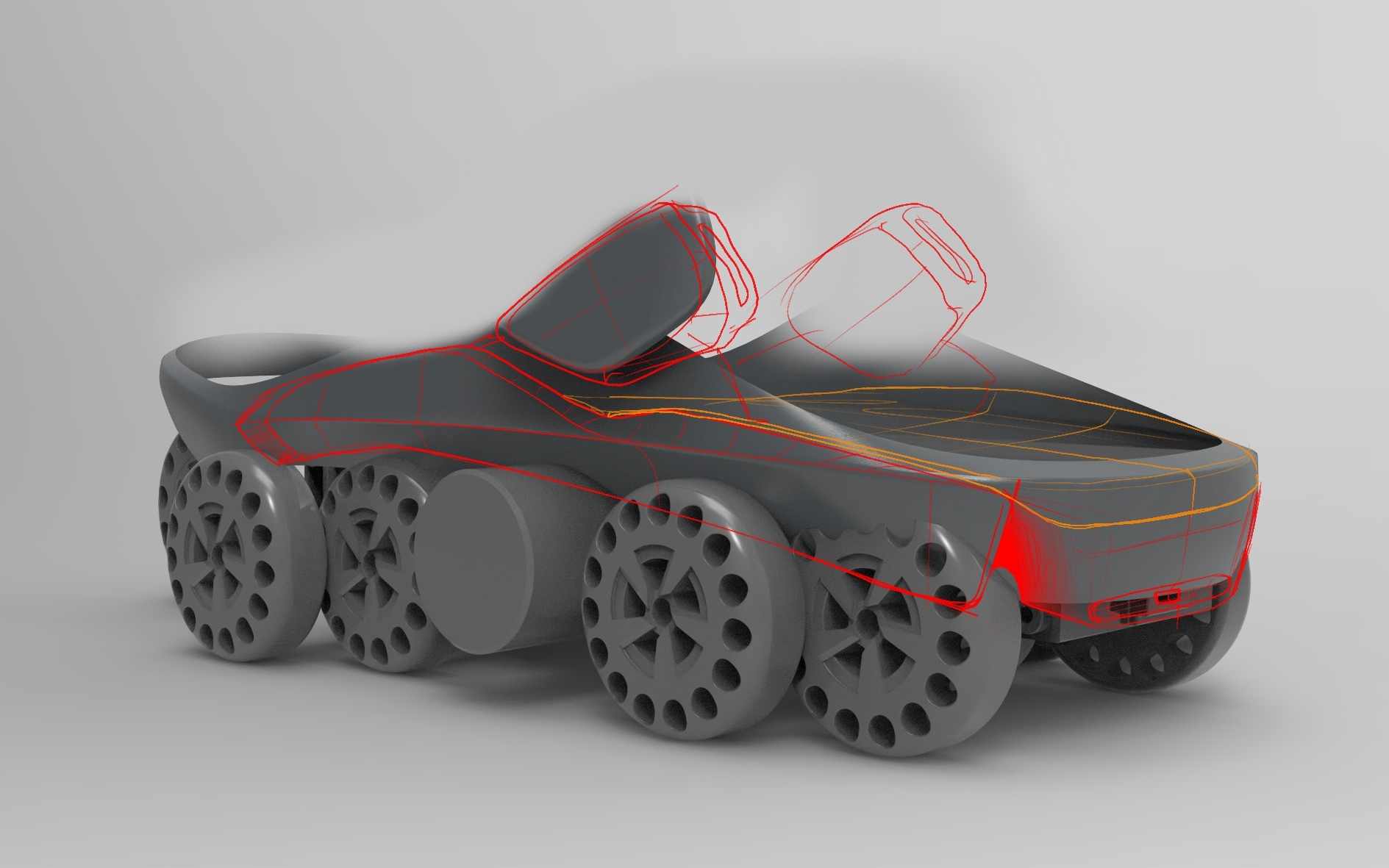

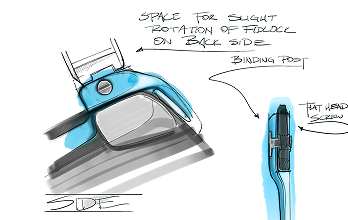

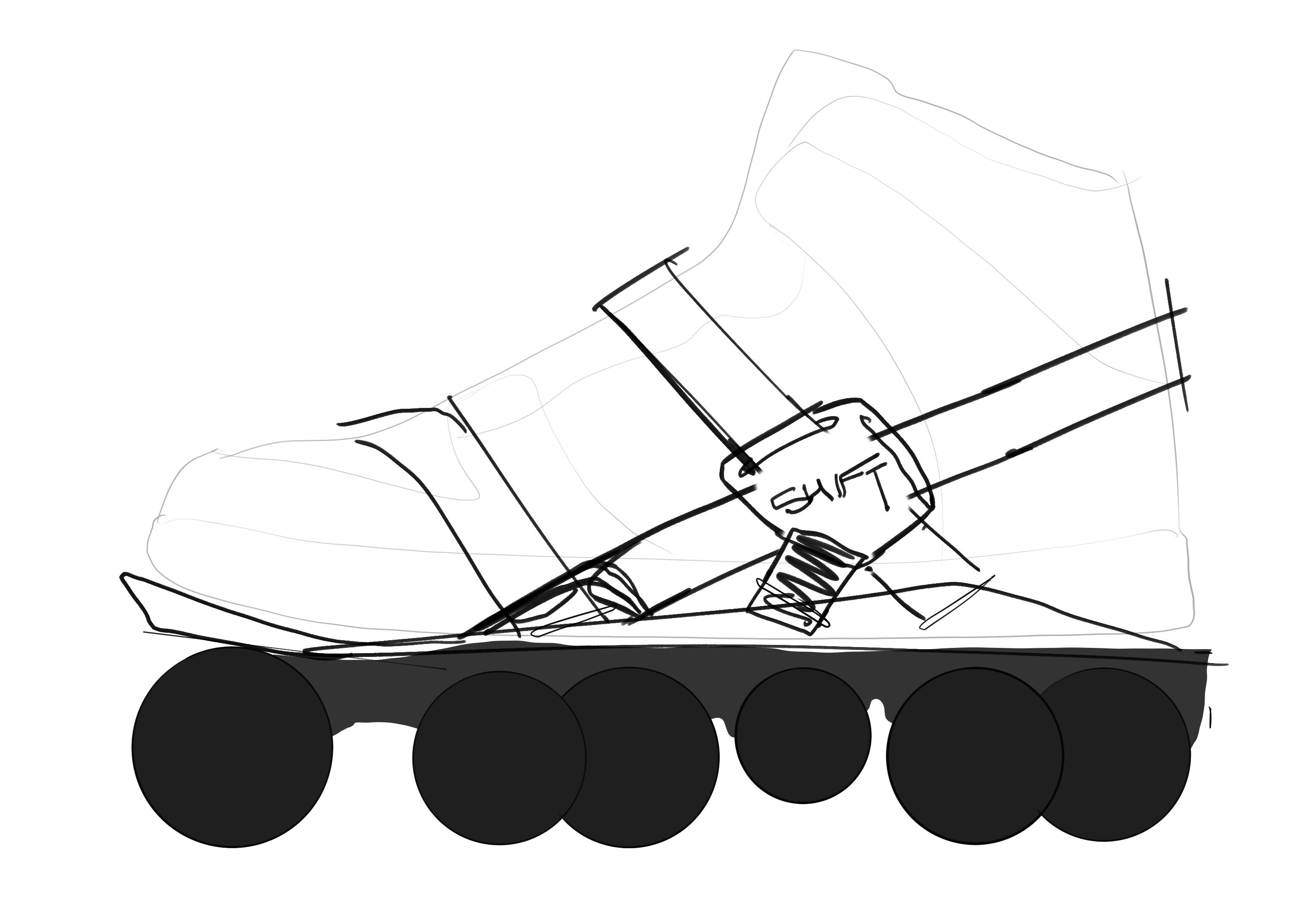

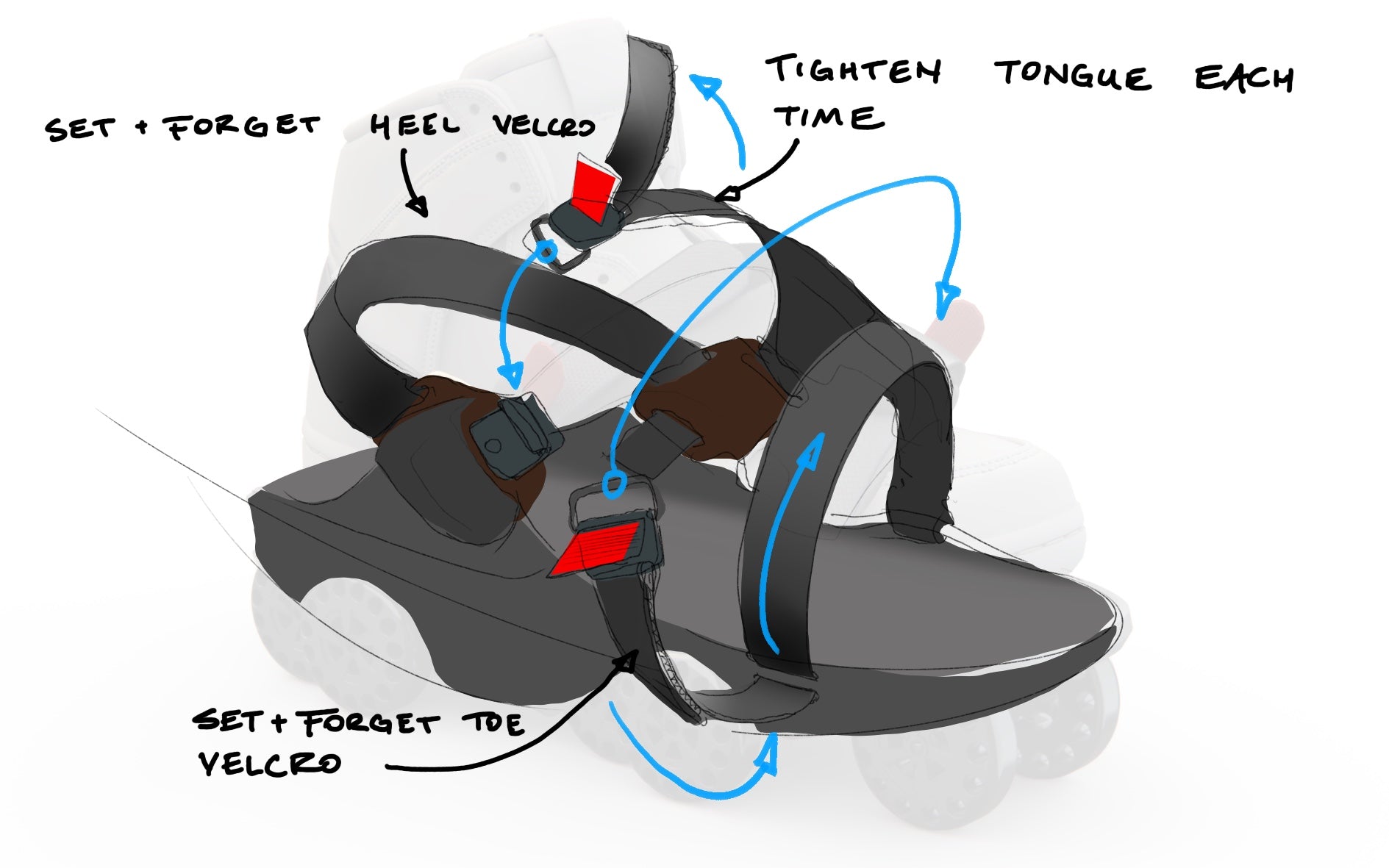

Design process sketches

Unique product teams

The best of the best

Veterans from Carnegie Mellon, University of Michigan, UC Berkeley, Nike, DJI, Rolls-Royce, and Tesla, bringing a diverse range of expertise spanning exoskeletons and humanoid robotics, footwear design, advanced electric motor and battery control, and manufacturing.

Motion capture lab

Study the fundamentals of human movement

Our motion-capture lab is a full-scale biomechanics observatory where we build a ground-truth feedback loop between the wearer and the robot. Twenty sub-millimeter-accurate Qualisys cameras fuse with a Bertec Fit 5 instrumented treadmill and a 6-DOF force-plate terrain rig to deliver synchronized kinematic and ground-reaction-force vectors in real time—even on emulated sand, grass, stairs, and ramps. These high-resolution datasets feed directly into our adaptive control stack, allowing us to optimize Moonwalkers and next-gen lower-limb exoskeletons with neuromuscular-informed gait models, rapid closed-loop validation, and data-driven parameter tuning that make the devices feel like an extension of the user.

The factory is the product

How vertical integration powers Shift Robotics

Vertical integration is key to Shift Robotics’ ability to deliver precision, durability, and performance. By controlling everything from machining to surface treatment in-house, we ensure every component meets the highest standards—enabling faster innovation, reliable quality, and efficient scaling as we redefine personal mobility.

Sustainable materials

Responsibly and minimally designed packaging

Our packaging is designed with sustainability in mind, using raw, responsibly sourced materials and recyclable composite cardboard. With a minimal material approach, we reduce waste while ensuring protection and a refined unboxing experience.